Industry in the Netherlands

Less than thirty years ago the Dutch economy relied mainly on trade, shipping and agriculture; since then the structure of the economy has altered considerably, with the rise in the importance of industry and manufacturing, to the point where industry is now the most important sector both in terms of population employed (44 per cent) and contribution to national products (42 per cent).

The reason for the rapid rise in industry-especially since the Second World War-is the same as that which created such great opportunities for trade and shipping in the past centuries, i.e. the position of the Netherlands on deep, navigable waters in the heart of Europe. It occupies a central position among Scandinavia, the United Kingdom, Germany, Belgium and France.

Now, as in the 17th century, the Netherlands is the gateway to Europe and a magnet for industry because timely provision was made in port areas for large industrial sites alongside navigable channels.

They attracted basic industries such as iron and steel Hoogovens', Ijmuiden, is one of the most modern steelworks in the world), oil refineries and, finally, extensive petrochemical plants. But it is not only in the vicinity of the big ports of Rotterdam and Amsterdam that the features of modern industrialisation are found in other parts of the country, too an industrial renaissance has taken place that has fundamentally changed the Dutch economy. This development was encouraged not by the presence of minerals in the soil, but by geographical location and communications.

The mineral resources of the Netherlands are very modest. There is some coal, but at such depths that it can barely be mined competitively.

Netherlands: Towns and Industries

Oil is also present in small quantities, but sufficient only to meet 10 per cent of the country's requirements. The two minerals which are found in large quantities are salt and natural gas.

Sail is found in the eastern part of the country at a depth of 300-400 metres (950-1,250 ft.), with some deposits over 45 metres thick, enough to meet the entire world demand for a hundred years. The Royal Dutch Salt Mines have developed a chemical industry based on the salt extraction; the deposits furnish the raw material for a soda plant on the sea coast and for a plant for the production of industrial salt.

In 1960 major reserves of natural gas were discovered at Slochteren in the northern province of Groningen. This find has turned out to be one of the biggest in the world and proven reserves amount to no less than 1,650,000 million cubic metres. Production has grown rapidly and has already altered the country's energy position.

Natural gas consumption made up 16 per cent of the total energy consumption in 1967 but is expected to rise to 22 per cent by 1975, which is equivalent to about 50 per cent of the production of natural gas. The remainder will be exported and so make a valuable contribution towards improving the balance of payments. Natural gas is also a boon to industry.

It was thanks to natural gas that an aluminium plant could be established at Delfziji (Aldel).

Industrial Areas

The western part of the country, or the West Holland Conurbation (Randstadt) as it is called, with its big ports of Rotterdam and Amsterdam, has always been the magnet to which industrial establishments were attracted and it is, therefore, logical that the basic and heavy industries are to be found there. It is there that they have both the deep-water harbours they need for importing raw materials and exporting their products and also the necessary communications by road and waterway with the hinterland. However, it is not only Western Holland which has undergone the process of industrialization.

Large centres of the metal manufacturing, electrical and textile industries are also to be found in the east and the south of the country, while a large-scale chemical industry has sprung up in the south of the province of Limburg as an offshoot of the coal mines there. Until recently there was little industrial development in the north, but salt mining and the availability of natural gas have attracted a chemical works and an aluminium smelting plant which have together formed the nucleus of a growth area around Delfziji. Factories processing agricultural produce and public utilities are to be found all over the country.

Chemical Industry

This industry has seen the greatest rise in expansion and production of any of the economic sectors since the end of the Second World War. It accounts for roughly 17 per cent of the Netherlands total exports. One of the causes of this rapid post-war development was the establishment and expansion of oil refineries and the chain of chemical works which followed after.

Another cause was the fact that very large Dutch companies not involved in chemicals began to venture into the chemical field, for example Royal Netherlands Blast Furnaces and Steelworks, Philips, Shell and Unilever and the State Mines. A third factor has been the establishment of the E.E.C. (Common Market) which has given the Dutch chemical industry a much larger market for its products. The chemical industry is distributed according to the raw material it uses. For example:

- chemical products extracted from coal have the chemical works based on the Limburg coalfield especially around Maarstricht;

- chemicals based on salt have the industry in the east on the salt deposits, for example in Hengelois the world's biggest vacuum salt factory. In 1967 it produced over 1,240,000 tons of salt and 37,000 tons of chemical products;

- the largest concentrations of chemical works are those around Rotterdam and Amsterdam which make use of oil as their raw material.

The favourable location of Holland and the rise of Rotterdam to being the world's number one port has convinced several foreign chemical and oil-refining companies of the importance of having a refinery or chemical works in close proximity to Rotterdam, to take advantage of its supertanker berth facilities, and its position on the Rhine, with access to the interior of Europe.

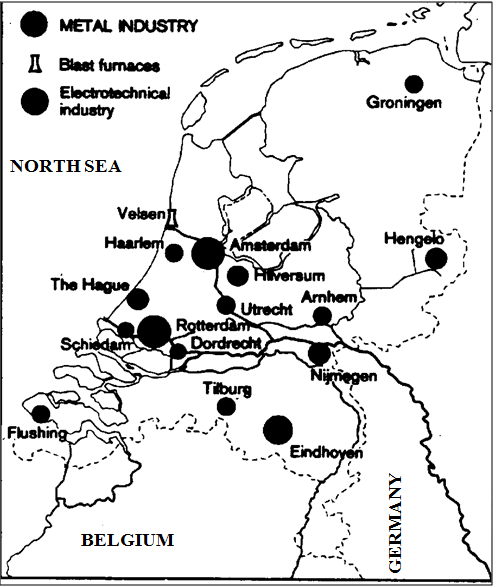

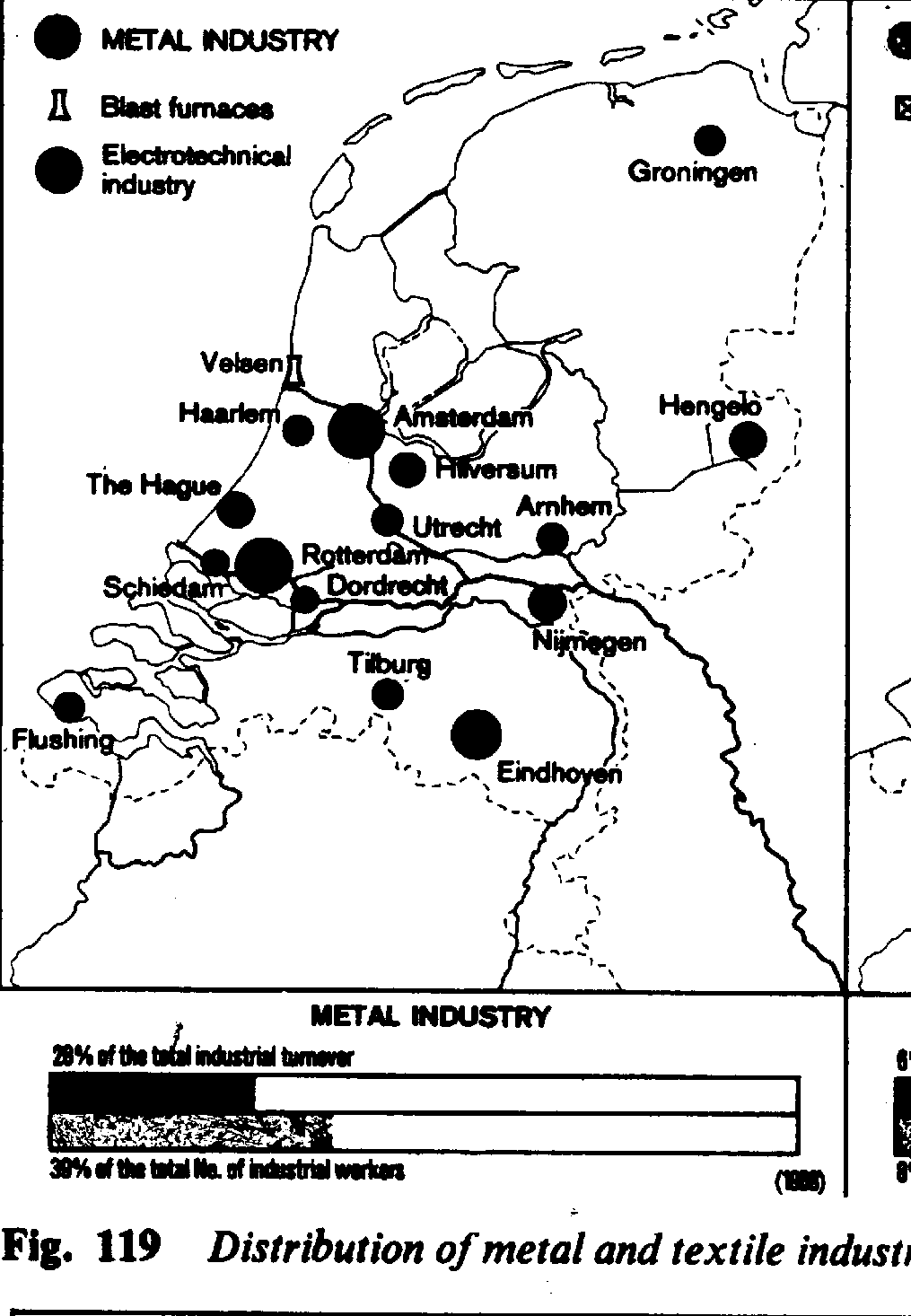

Metal Manufacturing and Electrical Industries

This industrial sector is the largest employer of labour in the whole of the Netherlands. A quarter of the working population earns its livelihood in this sector.

It is not only a large but also a variegated industrial sector, including basic, semi-finished and end products.

The Netherlands has one of the biggest blast furnaces in the world (Hoogovens) situated at Ijmuiden on the coast at the head of the *New Waterway' canal linking Amsterdam with the North Sea.

As has already been stated, Holland's minerals do not include iron-ore and so the decision to build an iron and steel works had to take into account a place where the raw materials necessary, i.e. iron-ore, coking coal and limestone, could easily be brought together, preferably near a large populated area, so that finished goods would be close to an available market.

The iron and steel works at Ijmuiden fulfils these conditions ideally, in that its position on the coast enables the raw materials to be easily imported, and the canal linking it to Amsterdam provides access to a large market. The steel works at Ijmuiden is producing four million tons of crude steel per annum, which is fabricated into tubes, plates, sheets and tin plate.

In addition to Hoogovens, there is a second large steelworks called Nederlandse Kabelfabrieken (Nether- lands Wire and Cable Factories) with an annual output of 300,000 tons of crude steel for manufacturing wire rod and steel strip. The amount of pig-iron produced from these two steelworks is far in excess of home demand, which allows the Netherlands to be among the world's largest pig-iron exporters.

Besides iron and steel products, the Dutch have established themselves as large producers of refined non-ferrous metals. The new aluminium works at Delfziji using natural gas as its heating source, has an output capacity of 130,000 tons per annum. Other metals refined are lead (15,000 tons per annum), zinc (41,000 tons) and tin (12,000 tons).

Tin extraction is particularly important; not only because Holland is one of the principal producers, but also because a great part of the production is made available for export. Many firms are engaged in the re-smelting of scrap, and an even greater number in turning semi-finished products into finished goods. Considerable quantities of these are exported: ship propellers and church bells are good examples.

The Dutch electrical industry covers every field of electrical engineering, with products ranging from complete power stations to tiny transistors. The emphasis, however, is on the manufacture of radio and television sets, lamps and household appliances, and in this sector the Dutch firm of Philips is world renowned. The town of Eindhoven in southern Holland is the home of Philips. The company is one of the largest in the world and accounts for 10 per cent of Dutch exports and provides jobs for about a quarter of a million people all over the world.

Netherlands: Major towns and industries

Food, Drink and Tobacco Industry

This is the dominant industrial sector in terms of turnover and it may be regarded as the country's oldest traditional one. Originally it was the natural outcome of having farming as the most important sector, but as this is no longer so, it can only be explained by the high quality of Dutch food products.

The industry processes both the country's indigenous products (milk, fruit, vegetables, meat) and produce of foreign origin (tea, coffee, cocoa, tobacco, oils and fats). Although a large part of the industry's output is sold on the domestic market, the export trade is one of its mainstays.

Important export products are dairy produce, meat and meat products, beer and spirits, tobacco products, for example cigars, tinned fruit and vegetables, potato starch, cocoa and cocoa products.

Textile Industry

The Dutch textile industry employs approximately 100,000 people and has had to undergo many changes since the end of the Second World War. From a geographical point of view it is one of the best industries for illustrating the way in which external factors and forces can bring about change to a traditional industry.

The major change has been the merging of individual firms so as to provide a united front, in order to be able to withstand competition from low-wage countries and countries whose textile industries are state run.

To illustrate this point, 86 per cent of the total spinning capacity is now concentrated in the hands of six large companies and 72 per cent of the weaving capacity is also in the hands of six companies.

The amalgamation of several small companies into one big company has enabled production to be modernized, specialized and rationalized, and it is these three forces combined which have enabled the Dutch textile industry to continue, despite intense foreign competition.

The second change to affect the industry has been the switch from traditional yarns such as cotton, wool and linen, to the synthetics of rayon and nylon. The reduction in demand for the traditional yarns caused many of the smaller textile companies to close down, and several others preferred to merge.

The distribution of the industry is widespread, with the synthetic industry localised at Arnhem, Breda, Ede and Nijmegen. The cotton industry is found in eastern Holland at Almelo, Enschede and Hengelo. The woollen industry is centred in the greater sheep-rearing legion of the Limburg at Maastricht.

Other Industries

(a) Draw a sketch map of the

Netherlands and on it mark and label the following:-

(i)

Industrial centres, Amsterdam. Rotterdam and Hengel.

(ii)

Rivers Rhine and Meuse (Maas)

(iii) North Sea,

(b) Explain the factors which

influenced the location

(i)

Rotterdam

(ii)

Hengel.

(c) Outline the problems caused by the

establishment of industries in the centres marked a (i) above.

(d) What are the steps being taken to

solve the problems in c) above.