Industrialization in Germany

Germany is one of the major industrial nations not only in Europe but also in the world as a whole. Her most important industries are based on coal fields though some other raw materials like iron ore, timber, hides, skins, wool, flax and other farm products are also important.

Until after 1850 most industries in the country were light in nature and majored in the products of handiwork like textiles, toys, pottery ware, and musical instruments. But between 1875 and 1914 industrial development in the country was damn fast.

Industrial development in Germany reveals, among other things, two basic aspects namely, the political history of the country and the great difference in raw material endowment between the western and eastern parts of the country.

Western Germany has more extensive industrial areas than eastern Germany. They include the Ruhr-Westphalia region- the middle Rhine area and several Small industrial towns like West Berlin, Munich, Hanover and others.

In the eastern part of the country the major industrial establishments are based on the Saxony coalfield and Stassfurt salt deposits. Here several chemical industries have sprung up in towns like Halle, Stassfurt, and Magdeburg.

At this juncture it is worth looking at Germany's natural resources as a basis for her industrial development.

Though not lavishly endowed with iron ores, originally Germany had considerable reserves of this important mineral in the middle Rhineland and ores of lesser value in Hanover. There is also some little iron ore in the eastern region of the country.

Germany also has generally good quality coal in the Ruhr, Saar and Silesian coal fields. There were also extensive deposits of lignite in the lower Rhine, Saxony and in the alpine foot hills. These deposits have always yielded considerable quantities of fuel.

Formerly there were sizeable deposits of copper, and pyrites. Uranium in the Erzebirge and Harz Mountains in the east also formed the basis for the metallurgical industry.

The country's chemical industry has its basis upon the huge deposits of salt and potash in the Rhine region and in Saxony.

The country has a variety of other resources including wool, flax, hides, skins, and timber. The textile industry owes much of its development to home-grown wool and flax which have for long been used for weaving and manufacture of linen cloth, respectively.

Timber from the black forest and water from the major rivers like the Rhine, Elbe, Ruhr, and Wupper are no less significant. Population is another indispensable resource in the Germany industry in as much as it produces and consumes industrial articles.

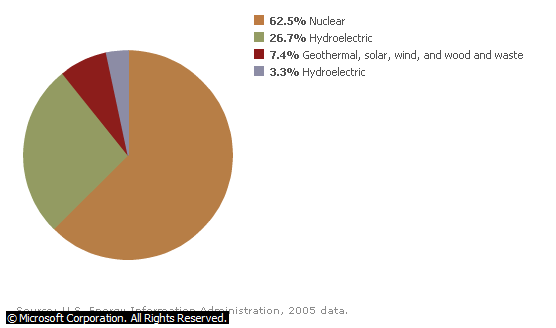

Germany Electricity Production

Characteristics of Germany industry

Germany industry has several distinguishing features. The salient ones are as follows:

A highly concentrated heavy industry which is involved in iron and steel production as well as heavy engineering. The latter produces such things as girders, bridges, boilers and mining equipment.

A highly developed chemical industry based upon the coal, salt, and potash deposits.

A widely dispersed pattern of industry i.e. industries are found in isolated centres and manufacturing towns like Hamburg, Munich, Saxony and Wurtemberg.

There is large-scale production of substitutes; synthetic, and derivative materials. Germany was a pioneer in utilising the by-products of industry material originally regarded as waste.

A very wide range of manufactures ranging from light goods like textiles and toys to steel products and ships.

Germany industry is largely dominated by great monopolistic combinations like the firms of Krupp (for iron and steel) and I.G. Farben for chemicals.

Ruhr Industrial Complex

As a case study, we are going to examine the Ruhr region as one of the vast industrialized areas in Germany. Complex not only in Germany but also in the whole of Europe. It is the biggest coal producer, iron and steel producer, chemical centre as well as engineering centre of Europe.

Position

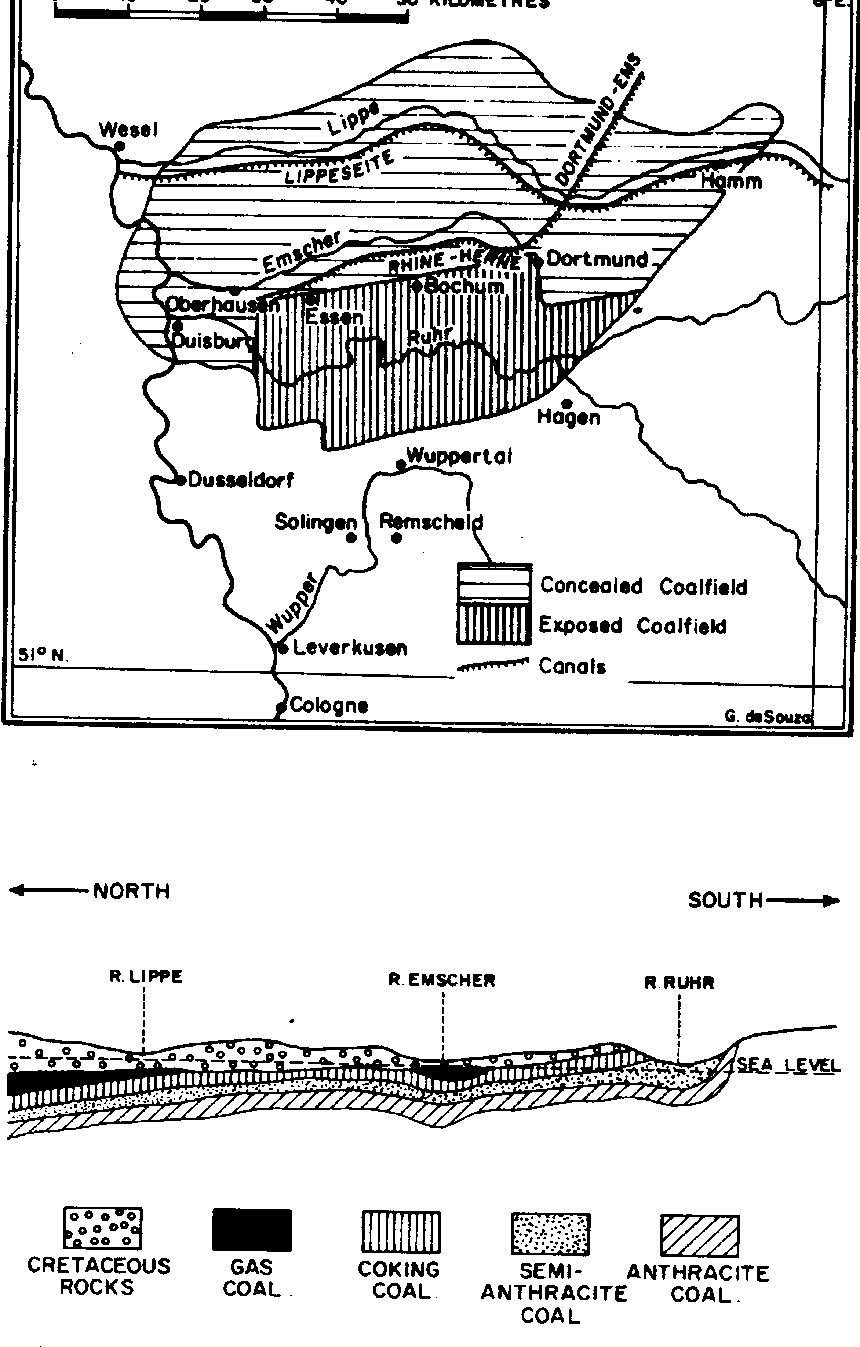

The Ruhr is found in the northern margin of the Rhenish uplands in West Germany. It is enclosed by three tributaries of R. Rhine namely R. Wupper in the south, R. Ruhr from which this region derives its name and R. Lippe in the northern part. It is located in the western part of Germany and it owes much of its development to the presence of the Ruhr coal field.

It has evolved over the years as an important iron and steel producing centre. Today it is the leading coal and steel producing area in Europe.

This industrial region is enclosed by rivers Lippe in the north, Wupper in the south and the Rhine to the west, while the Ruhr river runs right through the conurbation.

The extent, size and population of Ruhr industrial region

The Ruhr region stretches from west from Duisburg on R. Rhine to Dortmund in the east for 72 km; and about 60 km from north to south.

It is composed of towns, each over 100,000 inhabitants and three of these towns with over 700,000 people. These towns make up a cornubation population. The total population is over 10 million people. The main towns are Wessel, Dortmund, Bochum, Dusseldorf, Duisburg, Mülheim, Essen, Wuppertal, Solingen, Hagen Krefeld, Leverkusen, Oberhausen and Remscheid among others.

Map of the Ruhr region in Germany

So concentrated are the industrial towns of the Ruhr that the region has grown into an industrial conurbation. Today it is not easy to identify the individual manufacturing towns though each of them still bears its local place name.

The establishment of industry in this region started sometime before 1850, when coal was for the first time mined in large quantities. But after 1850 there was rapid industrial development.

The presence of coal meant that steel would be produced cheaply and economically.

Besides the iron, and steel industry there are several other industries which have been attracted by the locational advantages in the region. They include the:

- chemical industry,

- textile industry,

- engineering industry, paper, rubber, glass and

- pottery industries.

The availability of coal as a source of fuel especially in the past was the major factor, which attracted all these industries to the Ruhr. But in the modern times the most important locational factor is the availability of easy and cheap transport for moving bulky raw materials.

Communications have been improved upon by the building of canals like the Dortmund-Ems, and the Rhein-Herne. Railways and modern roads are also very significant.

Factors for the Concentration and Development of Industry in the Ruhr Region

Although different types of industry have developed in the Ruhr Cornubation, each with special locational advantages, some generalization can be made about the factors accountable for this industrial concentration and development. These include:

Presence of coal deposits. The Ruhr coal field yields different types of coal which are largely suitable for cooking. This attracted the iron and steel industry together with other related industries to the Ruhr. More so, all industries started with coal as their source of power.

Availability of local iron ore. This was a primary factor in attracting the early iron and steel industry, which specialised in agricultural implements. Originally iron ore used to come from the nearby Siegerland plateau.

Availability of other raw materials for the textile and chemical industries. These included wool, flax and the by-products of the coal mining industry. Today the chemical industry is oil-based.

Availability of water provided by the rivers bordering and crossing the Ruhr region have always provided all the water needed in the different industries.

Cheap water transport. The region is blessed with easy and cheap water transport. This has allowed the importation of raw materials as bulk as well as the shipment of finished products. The construction of canals has made water transport more dependable.

Water transport at Hamburg Harbour is the second-largest port

city in Europe and ninth-largest port in the world.

Wide market. The Ruhr region and Germany as a whole provide a large market for industrial products especially of the consumer type. The Ruhr alone has a population of 10.5 million persons most of whom enjoy high standards of living.

Government assistance to industrialists. The German government has come in to assist in further industrial development by improving upon roads, water ways, railways and other systems of communication. Government has also encouraged merging in the key industries, like the iron and steel industry, so that they can operate more efficiently and economically.

Availability of skilled labour. The large population in the region has always provided man power for a wide range of industrial activities. The industrial workers are highly skilled, well trained and by the fall of the 20th century they have already acquired the asset of experience.

Availability of land. In the early days, land was available for the establishment and expansion of industries. Unfortunately, today this factor is becoming less important since land is increasingly becoming scarce.

The earlier investors. The initiative of earlier investors like the Krupp family at Essen, Mayor at Bochum, Thyssen and I.G Farben attracted other industries. For instance, more industries have come to concentrate around Essen because it was the headquarters of The Kropp family.

The acquisition by Germany in 1871 of the Lorraine iron ore field and Alsace coal field from France brought into Germany a population with great skills in iron working and coal mining. This boosted the production of steel in the Ruhr and elsewhere in Germany.

The major industries of the Ruhr and the important towns concerned

The Coal Mining Industry

The Ruhr is the most important coal producing region in Germany. It produces about 122,000 million tones and this accounts for over 80 percent of the country's annual output. This region has the largest coal field in the whole of Europe. It is also the most economic to work. The Ruhr coal field was made up of two parts, namely:

The exposed part, in the south, which was the first to be worked and has got exhausted, and

The concealed part, in the north, extending up to the valley of river Lippe. At present all the coal produced in the Ruhr comes from the pits in this part.

The development of the coal mining industry has been favoured by the presence of large reserves of generally good quality coal and of different types. The lower seams contain anthracite, and above them lie coking coal, gas coal and flame coal, respectively.

There are about 100 coal mines in the Ruhr but much of the output comes from 36 mines. This industry employs about 25 percent of the industrial working population of the Ruhr conurbation.

From the middle of the twentieth century this industry has undergone great changes. For instance, there has been a decline in coal output; and the number of workers employed has been reduced. These changes have resulted from several factors including the reduction of coal mines operating in the region from 252 to only 100 and competition from other sources of power such as oil and hydroelectricity.

The Iron and Steel Industry

This is the second largest industry for this region. It has been the oldest form of industry and the greatest consumer of coal especially coking and Bituminous coal. The raw materials needed for iron industry are iron ore, limestone and coking coal used as fuel.

The iron and steel industries include Blast furnacing, steel mills, hot rolling, cutlery, pressing and drop hammering, industrial works, car and locomotive industries. More than 80% of these industrial enterprises are located on the Ruhr.

The main centres for iron and steel industries include Duisburg, Essen, Bochum, Dortmund, Gelsenkirchen which perform more or less the same industrial activities.

Favorable factors

The availability of coking coal for smelting iron ore among these industries.

The availability of iron ore from Lahn and Sieger valleys on Germany and from Lorraine district on Eastern France and Sweden which is easily transported along R. Rhine via the Dortmund - Ems canal to the centre named above.

The presence of local skilled labourers who knew a great deal of metal work.

The need to mechanize agriculture gave rise to the manufacture of ploughs. Tractors, combine harvesters.

The rise and development of heavy industries gave rise to the manufacture of trains , lorries, ships, diesel engines, generators, among others, and cars many of which depend on iron and steel.

The increasing construction of good roads and railways has brought a great demand for the manufacture of steel bridges, specially used at crossing points on both rivers and canals.

A. The Textile Industry.

The demand for clothing and easy transport of raw materials by water led to the growth of the textile industry.

The German textile industry is practically made up of several industries each having its own specialty. They include those producing cotton, woollen, silk; rayon, and linen products.

There are also those specializing in the production of footwear. In the Ruhr region the manufacture of textiles has become an important activity m tin: towns of Wuppertal and Krefeld. The development of textile industries in this region has been favoured by the following advantages:

There was prosperous sheep rearing on the uplands surrounding the Ruhr valley, which provided wool for manufacturing cloth in the early industry.

Flax, another raw material for making cloth, was locally grown on the loess soils then as now. The linen cloth produced from flax is superior to cotton cloth both in durability and smoothness.

The availability of soft fresh water from rivers Rhine and Wupper has also been important. This water is used in bleaching and dyeing of textiles.

Cotton which was not readily available at home was imported cheaply via the river Rhine. In the modern times cotton has been replaced by synthetic fibres for example rayon which can be produced locally.

Availability of power especially steam power, which was provided by coal from the Ruhr coal field. Later hydroelectricity was developed.

There has always been a large domestic market for textiles like high equality linen sheets, table linen cloth, and foot wears.

The presence of anthracite coal of both the exposed and concealed coal fields.

The damp climate suitable foe spinning and weaving of cloth.

The availability of clean and abundant water used for mixing dyes and bleaches from which designs for clothes are obtained and also to cool machines.

The presence of skilled labour for making clothes and rich men who could provide capital for manufacturing textile machinery for example looms, spinning machines, sewing machines and setting up industries too.

Good communication along R. Rhine allows the import of raw - materials like cotton from Egypt and Sudan etc and the export of finished textiles abroad. This industry is however, dominant in the following towns as shown below:-

Krefeld: Specialize on silk, velvet teyrlenees as well as rayon (made from oak fibre)

Düsseldorf: Specializes in women clothes, foot wear, it is an international fashion centre.

Wuppertal: Specializes in cotton rayon and woolen clothing industry. It makes carpets as well as chemical namely dyes and bleaches for her textile industry. It now manufactures spinning machines, looms and sewing machines.

Gladback: Specializes in making machines which are used on the textile industry and in some synthetic and rayon clothes.

The Chemical Industry

This is another important industry in the Ruhr and it is the closest rival of the iron and steel industry. It employs over 2 million workers. The heavy chemical plants are centered around the towns of Leverkusen, Cologne, Düsseldorf, Essen and Bochum. The early chemical industry was based upon the coal, salt, and potash deposits.

Today fee major raw material for this industry is oil and the petro-chemical branch has developed rapidly. Its products include organic and inorganic chemicals; dye stuffs, drugs, synthetic fibres, soap, detergents and other chemicals.

The growth and development of this industry in the Ruhr region have been favoured by:

A ready supply of raw materials particularly from the coal industry and oil refineries. Other raw materials are salt, potash and local limestone.

There has always been demand for chemical products in the textile industry which uses bleaches- detergents and, dyes in cloth manufacture.

The local farming community also needed, and indeed consumed, large quantities of chemicals particularly fertilizer.

Water, as an essential raw material is also available in the rivers crossing and bordering the Ruhr region.

Uses from the Ruhr Coal Fields

Types of coal and formation stages

Peat Coal: This is still soft and is used in preparing gas for domestic purposes as fuel and its known as a Bog, peat coal in Britain. It is semi - decomposed.

Lignite coal: This is an already solidified rocky coal which burns with much smoke and is used in local homes as fuel. It is called Bituminous coal in Britain.

Coking coal (brown coal): It is 80% - 90% carbon. It is used for coking purposes. Once introduced in Blast furnaces (heat - boiless) it emits little smoke. Hence, it is useful in smelting ores at high temperatures for example in reduction of iron from iron ore and aluminum from bauxite.

Semi anthracite: This is almost pure coal (90% carbon). It is used in manufacturing of synthetic products or fibres.

Anthracite coal: This is pure high quality coal which is smokeless. It is used in making synthetic products and to prepare delicate chemicals on industries.

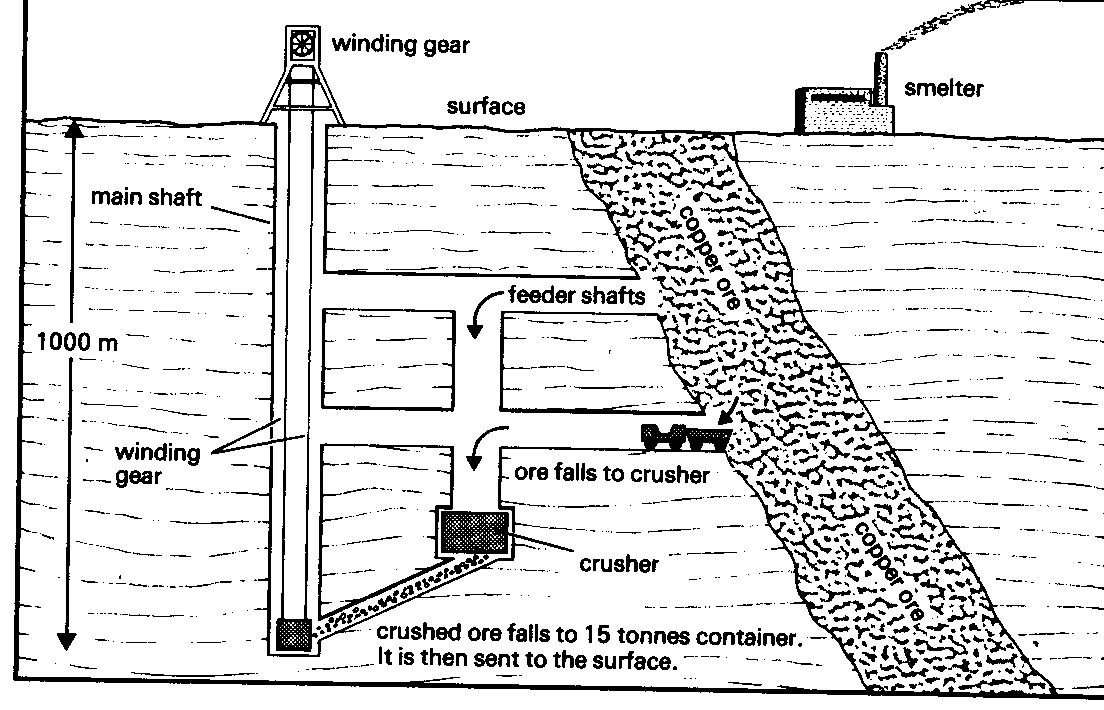

Mining of Coal

(1) Open cast method

This is simple and cheaper method of mining of coal and even other minerals which exist near to the earth's surface like exposed coal mineral resources.

Diagram showing underground mining

For open

cast, the miners use explosives by blowing off the top surface of the earth on

order to reach the deposits or seams of coal mineral rock.

For open

cast, the miners use explosives by blowing off the top surface of the earth on

order to reach the deposits or seams of coal mineral rock.

As for Adit method, the miners dig laterally, especially in a basin or valley region in order to exploit the resource.

Deep mining method

This is quite an expensive method it involves the digging and drilling of the underground beds of rock on order to reach the coal.

Later under ground tunnels are dug with corridors, supported by shafts for conveying light and air to the miners about ½ a mile deep.

The roofs are protected by pit - props of coniferous woods from falling in. However, mechanical faults and cracks are not unusual and often lead to disastrous accidents underneath.

German Coal Mining

Although

mining makes up only a small part of the German economy, some minerals are

still produced in large quantities, especially the type of coal known as

lignite. Much of the lignite in Germany is produced in surface, or strip, mines,

where machines remove dirt and rock from above the coal deposits. Some of the

machines used in German mining are the largest of their kind in the world;

so-called shovel wheels, like the one shown here, can do the same amount of

work in a day as thousands of men.

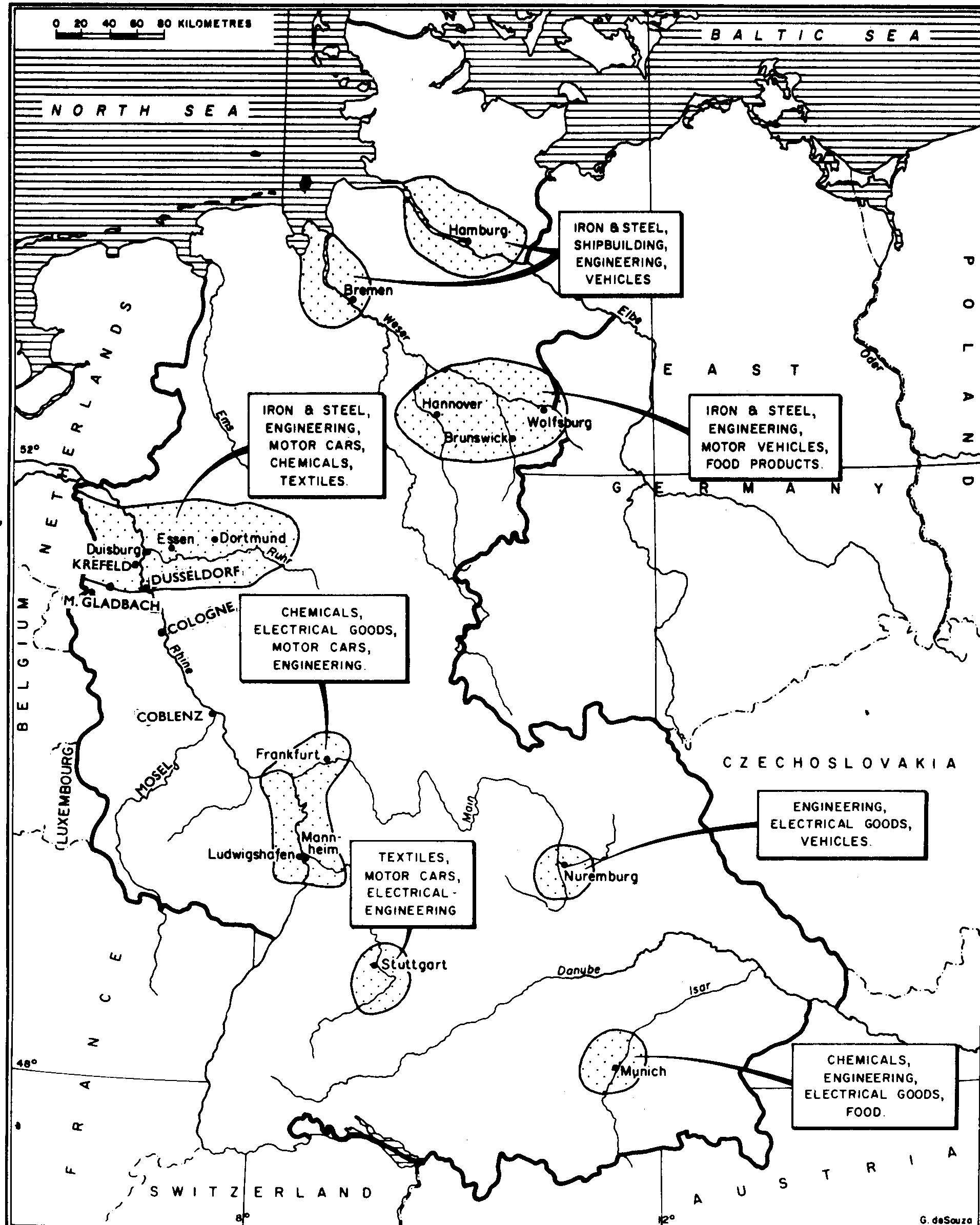

Other Industrial Regions in Germany

The Rhine - Main Industrial Axis:

It is located between River Rhine and River Main. Major industrial regions include:

Frankfurt

Located close to the western Rhine with its tributary Main. Because of this location, it has a focal point of communication.

It is also a commercial business centre and all railway links converge there. Has chemical industry that uses coal from the Ruhr. Big companies have been put up there for example, Opel Car Company in Russelheim.

Mainz

It is located on the confluence of Rive Rhine and Main. It is a universed town and at one time a home of Gutenberg the inventor of the printing, and the town is an important printing industry.

Wiesbaden

It has developed as a result of hot springs in the area. Some of them have been tapped to provide power to the industries. Thousands of tourists have traveled here to be cured of certain body diseases like: rheumatism and arthritis.

The Rhine - Industrial region

This region has many industries at Mannheim. It is the fifth major industrial town in Germany. Other smaller industrial towns include: Darmstadt. This town has specialized in chemical and pharmaceutical products like drugs and medicines. Other industries in this town produce detergents like soaps and dyes.

The North industrial region

This is another industrial region centred on the largest ports of the country for example Hamburg and Bremen.

Hamburg is number one port of Germany found 112 kilometres up the estuary of the River Elbe. It handles over 30 million tones of cargo every year and with over 60 kilometres of quays to deal with it. Hamburg also has its fishing fleet operating from the old town of Altona which now is merged with Hamburg.

The major industries in this industrial town include food processing, oil refining, soap making, ship building, chemical industries and textiles.

Bremen is the second largest port lying some 40 miles upstream on the river Weser. It handles over 15 million tones of goods annually. It has strong ties with USA because it handles all the cotton and Tobacco of the USA.

Aircraft Manufacture in Germany: Manufacturing

and heavy industry make up an important segment of the German economy. In

addition to being a leading producer of motor vehicles, cement, iron and steel,

and machinery, Germany also manufactures aircraft for Airbus, a major European

aerospace company. Shown here, an Airbus A321 is assembled at a facility in

Hamburg.

Aircraft Manufacture in Germany: Manufacturing

and heavy industry make up an important segment of the German economy. In

addition to being a leading producer of motor vehicles, cement, iron and steel,

and machinery, Germany also manufactures aircraft for Airbus, a major European

aerospace company. Shown here, an Airbus A321 is assembled at a facility in

Hamburg.

The major industries in Bremen include: ship building, cigarette manufacture and textiles.

Another industrial region is Brunswick and Hanover found in the bordelands.

Brunswick has developed as the market town for the region. It lies on the very fertile soils and has developed an intensive agriculture for vegetables and fruits which are canned, sugar beet, which is refined for sugar and the beet pulp being made up for cattle cake. Manufacturing industries in this area include vehicles, off machinery and pharmaceuticals.

Hanover is situated in the fertile loess belt known as the Borde. The manufacturing industries such as chemical, rubber, machinery, electrical and motorcars are found in this area.

Map of Germany showing Industrial Regions.

Factors that Have Contributed to Urban Development in the Ruhr Region

The Ruhr conurbation is the largest urban zone in Europe and most densely populated, where there are over 7 million people living in the area. There are over 13 towns each of which has a population of more than 100,000 people. This has been mainly due to a high degree of industrialization in the region. People earn a living here by coal mining, steel making, metal and engineering works.

Industrialization: Most of the towns started as simple mining centres. The diverse industrial activities taking place in this region have attracted so many people. Hence dense population is found here and has resulted into growth and expansion of towns within this region.

German Car Factory: Sparks fly as

cars are assembled at a plant in the port city of Regensburg. Germany has long

been a world leader in motor vehicle production, which is an essential

component of the nation's economy.

Fertile borde plains: These plains do provide food and have enabled towns to develop as market centres for example Bochum, Essen, Dortmund and others.

Good communication: The natural water ways especially R. Rhine and its tributaries namely R. Ems, R. Ruhr and R. Lippe , together with artificial ways like the Lippeseite canal, the Dortmund - Ems canal do facilitate cheap transport and have helped much to accelerate industrial growth and urban expansion on the Ruhr. The import of raw materials and export of finished goods along these water routes have promoted not only good international understanding and attracted much foreign trained labour but also boosted a lot of foreign trade.

Employment: The rapid growth of industries has attracted a lot of people as Ruhr has a wide range of banks, insurance, factories and industries depending on coal mining, iron and steel manufacture. They offer much opportunities of employment for job-seekers. Both the commercial and industrial activities on Ruhr attract a lot of people for various employment.

Electric cable trains

contributing to industrial development of Germany

Important Industrial Towns

Essen

Essen has a population of over 750,000 people. It is the largest city in the Ruhr conurbation. The growth of Essen much depends on the availability and mining of coal and the development of iron and steel industries.

It now has busy engineering works which produce heavy medium and light goods. It is important for her iron and steel works. It has railway and locomotive construction works, chemical and glass works, textile and furniture industries.

Dortmund

Dortmund is the second in size with a population of over 645, 425 people. It has been a trading centre as early as the 19th century and had business connections with Britain, Russia. Poland and the Scandinavia countries (Denmark, Norway and Sweden).

It had developed mainly due to the existence of both exposed and concealed coal deposits. It is linked to the North Sea by Dortmund - Ems canal.

It is the largest fruit and vegetable centre of West Germany. It has over seven beer breweries and is the home or headquarters of the largest bridges, building firms in the world.

Duisburg

Duisburg is a large industrial centre with a population of over 504,412. It is a river port situated at the confluence of R. Ruhr and R. Rhine. Duisburg is the western cornerstone of Europe's coal and iron industry where many by - products of coal, namely car and lorry tyres, dry cells, ball pens etc are manufactured.

It makes bicycles, cars namely Benz, Volkswagen and cutlery products. It has the biggest cranes, ass and diesel engine works in the world.

Mercedes Benz: The best car made in Germany

Düsseldorf

Düsseldorf has a population of over 705,122 people. It is an administrative centre on the Ruhr region. It has both iron and steel industries.

It is the largest textile industry specializing on women's clothes and famous banking centre in W. Europe.

Bochum

Bochum has a population of 710,000 people. It is situated near the coal field. Hence mining has attracted a lot of people for employment.

Iron and steel industries have been established as a result of coal mining. It produces goods like wagons, rails, lorries, lorry tyres, corrugated iron sheet.

Problems facing the Ruhr industrial Region

The amount of coal produced on this region has gone down from 150 million in 1950 to 112 million tons on 1970 and to 75 million tons on 1980, especially that from the exposed coal fields. Hence the need to mine the concealed coal and to import more from outside, like Britain and U.S.A though the costs of extraction and importation are high.

Some of the pits have been closed down as a result of a reduction of workers who are employed on mines. In 1967, 380,000 people were employed due to high rate of criminology and industrial strikes for increasing wages and improved working conditions. In 1969, 20,000 workers were laid off. Hence the need to build more prisons to reform criminals and organise and set up trade unions on order to improve the standards of living for these workers.

Iron ore available in Germany was reduced on quantity. Hence more had to be imported from Sweden and Eastern France from Lorraine district.

As many people were seeking for jobs in industries, there was need to cater for their accommodation and provide them with food. As a solution sky scrapers were built and more food grown in the Borde fertile region and yet more has to be imported.

There is sound pollution due to a lot of noise created by running vehicles and crying machines on industries. This disturbs the atmosphere. This was partly solved by constructing sound proof houses and offices in busy centres.

The pollution of the atmosphere with dangerous gases and poisonous chemicals. This was counteracted by constructing modern chimneys with instruments which could convert carbon monoxide produced on industries to carbon dioxide and oxygen readily useful foe human and plant consumption. Improved sewerage systems and pipes were set up to carry dirty water from industries to far off reservoir

a.

Draw

a sketch map of the Ruhr industrial area and on it, mark and name:-

(i)

Exposed

and concealed coal fields

(ii)

Canals:

Dortmund, Ems and Lipperseite.

(iii)

Towns:

Dusseldolf, Essen, Dortmund and Wuppertal.

(iv)

Rivers

Rhine and Emscher.

b.

Explain

why the Ruhr region is the largest producer of steel in Germany.

c.

Name

the :-

(i)

Other

two industries found in the region.

(ii)

Other

iron and steel producing areas in Germany.

d. What problems does

the iron and steel industry face?